-

Spare parts and repair material

- 3M product catalogue

- Batteries (rechargeable)

- Anemometer/Wind vanes

- Safety and protection

- Storage/ Container

- Automation technology

- Lighting technology

- Bergolin product catalogue

- Brake pads

- Brakes

- Condition monitoring systems

- Rotary encoders

- DEHN product catalogue

- Ice detectors

- Electronics

- Electrohydraulics

- Paints/Varnishes/Coatings

- Springs

- Filters

- Generators

- Gearboxes

- Glass fabrics

- Hydraulic parts

- Cables

- Cartridge guns

- Adhesives and sealants

- Carbon brushes

- Corrosion protection

- Couplings

- Fans

- Mankiewicz ALEXIT® BladeRep

- Measurement technology

- Mita-Teknik

- Motors

- Petzl

- Man and material transport

- Pitch drives

- Platforms for rotor blade repair

- Pumps

- Relays

- Repair services

- Rotor blades

- Rotor blade repair products

- Switch cabinets

- Hoses

- Abrasives

- Slip rings

- Slip ring transmitter

- Lubricants

- Bolts

- Shrink discs

- Sensors

- Servocontroller

-

Sherwin Williams - Corrosion protection

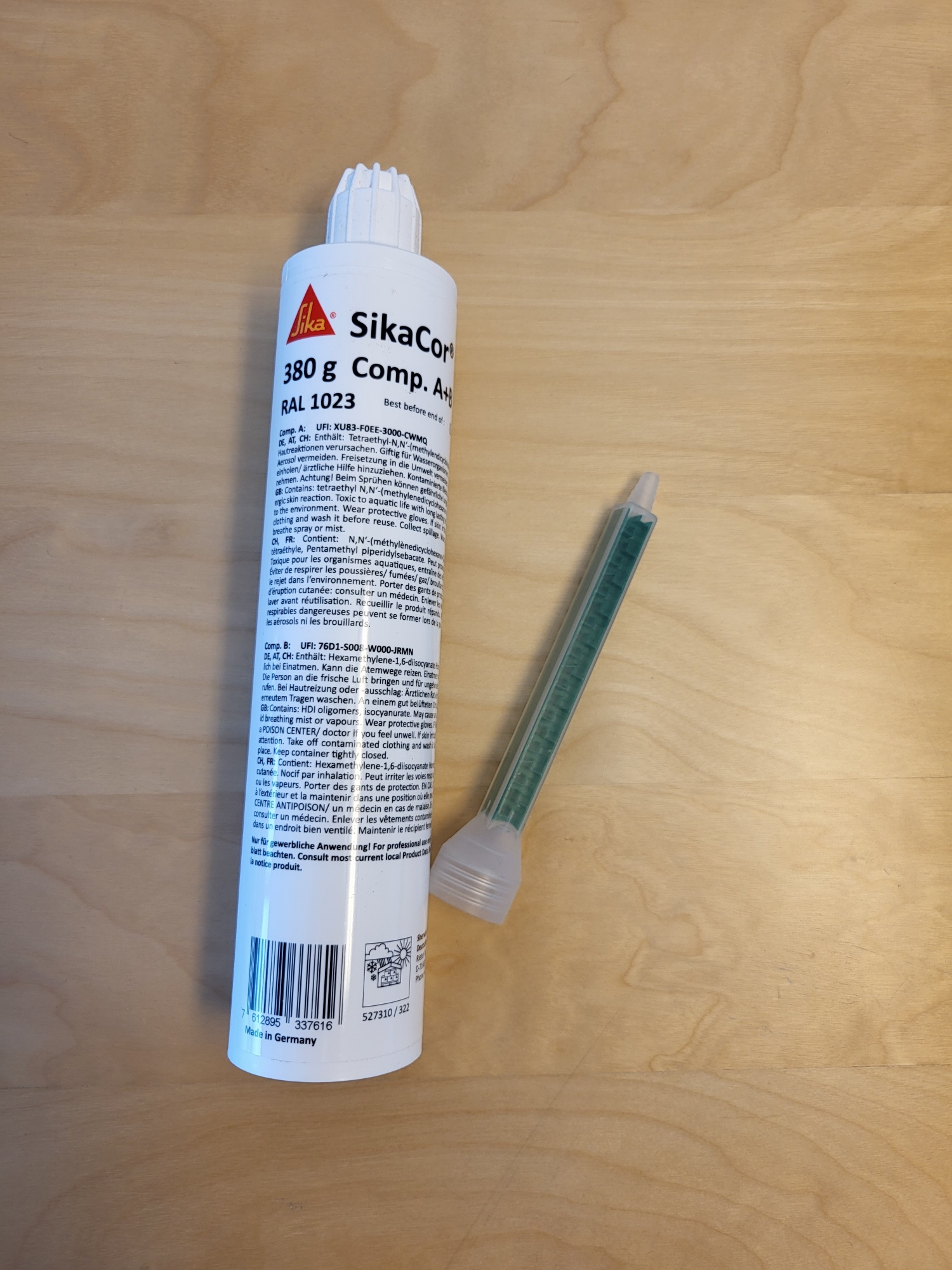

- Sika product catalogue

- Fuses

- SUZLON Product Catalog

- Tower repair products

- Uninterruptible power supply (UPS)

- Valves

- Consumables

- Maintenance and Lubrication

- Tools

- Roller bearings

- Accessories OEM

- About us

- Get in touch

Sherwin Williams - Corrosion protection

The corrosion protection products from the Sika Permacor and SikaCor series provide durable protection for steel towers indoors and outdoors. SikaCor also offers high-performance hydraulic steel construction products for foundation structures in the offshore sector as well as proven products for the economical corrosion protection of steel and cast iron machine components.

Onshore coating systems

For the corrosion protection of the tower segments and machine parts, the European standard EN ISO 12944 is used as a basis in the corresponding parts. The minimum requirements of the coating system are usually C5-M high according to EN ISO 12944-2 for tower outer surfaces and C4 high for tower inner surfaces and machine parts.

- Steel Tower

- Machine and attachment parts

- Repair and maintenance

Offshore coating systems

High demands are placed on corrosion protection for the construction of plants on the high seas. Difficult accessibility makes a partial renewal on site almost impossible. The coating systems must therefore be designed to withstand the demanding climate over their entire service life, about 20 - 25 years. Norms and standards for offshore corrosion protection are EN ISO 12944-6, ISO 20340 and NORSOK M-501. The minimum requirement for the coating systems is NORSOK M-501, System No. 1 for tower outer surfaces and C5 M-high for tower inner surfaces and machine parts.

- Steel tower and machine parts

- Foundation structure

- Repair and maintenance